GLULAM – Glued Laminated Timber

GLULAM is an engineered wood product manufactured by bonding pieces of wood laminate together- it consists of at least 3 timber laminates bound together with water resistant and durable adhesives running parallel with the member.

GLULAMs are carefully engineered to be able to support a building with maximum conditions and tensions forced upon it. In comparison with other common construction materials and timber, GLULAM is proven to sustain a high level of load-carrying ability along with stability. In recent times GLULAM has grasped the attention of the designers, builders and structural wood manufactures for its strength, stiffness and durability. it is considered stronger than steel as glulam can have longer distance span with minimal intermediate supports. Besides that the builders and designers can design very flexibly using glulam in any type of its applications.GLULAM with this high load-bearing capability, directional stability, product range of variations and magnificent surface properties gives it a wide range of use options in the construction area.

GLULAM & STABILITY

Glulam timber is well-known for its structural benefits:

- It comes in large unit sizes and long lengths – and also it can be designed in curve and straight. It is mostly used in construction as structural beams. Longer lengths

- can be possibly manufactured by finger joining.

- Glulam’s laminating process improves its strength. Comparing to other solid timbers, glulam has proven its higher strength over the other solid timbers because of its fewer natural defects and broader distribution. What makes glulam comparable to steal is that glulam is as strong as the steal but much lighter in terms of weight.

- High dimensional stability – since glulam made of seasoned timber, it makes it less subject to movement as a result of moisture content.

GLULAM manufacturing

Glulam members are produced in large sizes and long lengths with much higher strength compared to that of the individual member. It was impossible to produce much larger pieces with traditional solid-sawn timber but with glulam larger pieces can be manufactured. Due to the small size of natural defects in glulam, it makes it stronger than solid timber. Glulam is manufactured in finger-jointed so that longer lengths timbers can be made. While manufacturing glulam, laminates thickness is considered based on the applications and species use. Before gluing, lamination has to dressed exactly in uniform thickness and then they are compressed together with constant pressure until the glue is cured. After that, glulam panels can be designed and cut to the required exact sizes.

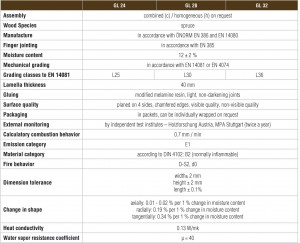

Glulam Technical Data:

Glulam is available in different lengths with detailed technical data as in the table below;

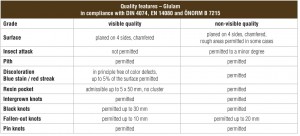

Glulam Qualities:

Glulam Special components

Glulam Benefits:

- Flexible: glulam is very flexible and it can be designed for many structural applications such as floor beam, beams for roof, columns, rafters, decking.

- Flexible: glulam is very flexible and it can be designed for many structural applications such as floor beam, beams for roof, columns, rafters, decking.

- Lightweight and strength: glulam is much lighter than concrete beams, it is only one third of the concrete’s weight but it can be as strong as concrete.

- Great appearance: its good looking timber makes it preferable over other materials such as steel and concrete besides that glulam creates very warm feel in the building.

- Durability: glulam’s durability depends on its structural specifications, wood species and application type. With the right specifications, glulam beams can last

decades in the most conditions.

- Fire Resistance: glulam timbers perform well in fires and it takes considerably long time period of time to char besides glulam does not deform like other materials such as steels. Glulam’s fire resistance can be further improved by adding other fine proofing finishes.

- Fire Resistance: glulam timbers perform well in fires and it takes considerably long time period of time to char besides glulam does not deform like other materials such as steels. Glulam’s fire resistance can be further improved by adding other fine proofing finishes.

- Economical: glulam is very cost competitive; while the glulam itself being cheap, its lightweight makes the transport and handling cost low which also leads to less complicated and low cost foundations.